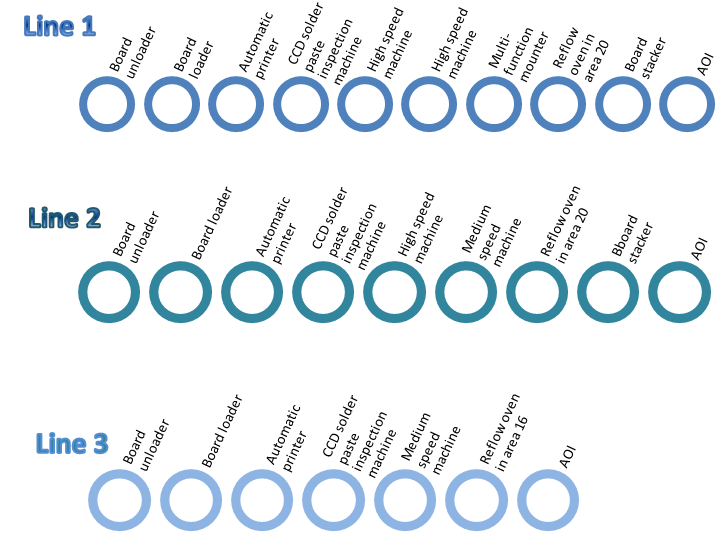

SMT

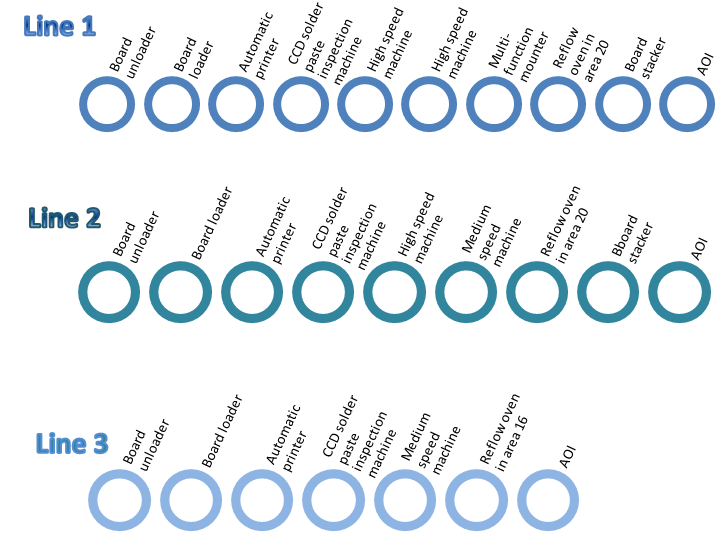

The three flexible lines of SMT capacity configuration that best suits customers’ specified product

component number or precision.

All lines are equipped with an EKRA automatic printer to improve the process yield.

Three units of TRI AOI products all undergo AOI testing to improve the product yield.

Whole area is entirely protected by static electricity to ensure products are free from static electricity

damage.

With care of every single details and great customer service, we use precise SMT equipment and process management to achieve competitive cost and quick delivery to satisfy our customers.

DIP/TEST/REPAIR

System burn-in room with a capacity of 200pcs.

ICT Test Station:

Equipment model :TRI Innovation TR-518FR

Electronic board processes OPEN/SHORT and defective parts testing.

BGA Repair:

Equipment model : Fine-Tech Electronics BGA 936USB

BGA Parts Repair and Replacement

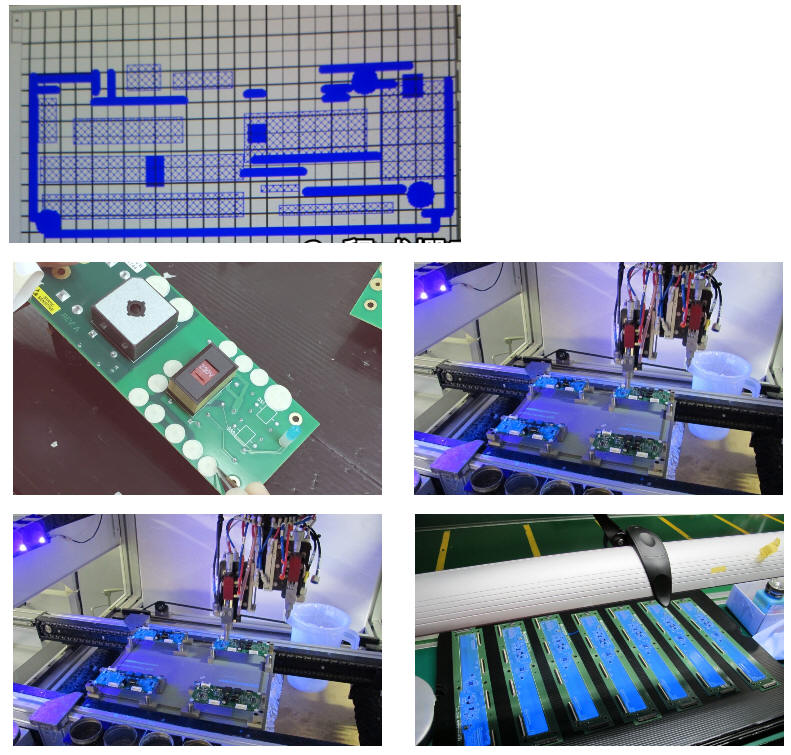

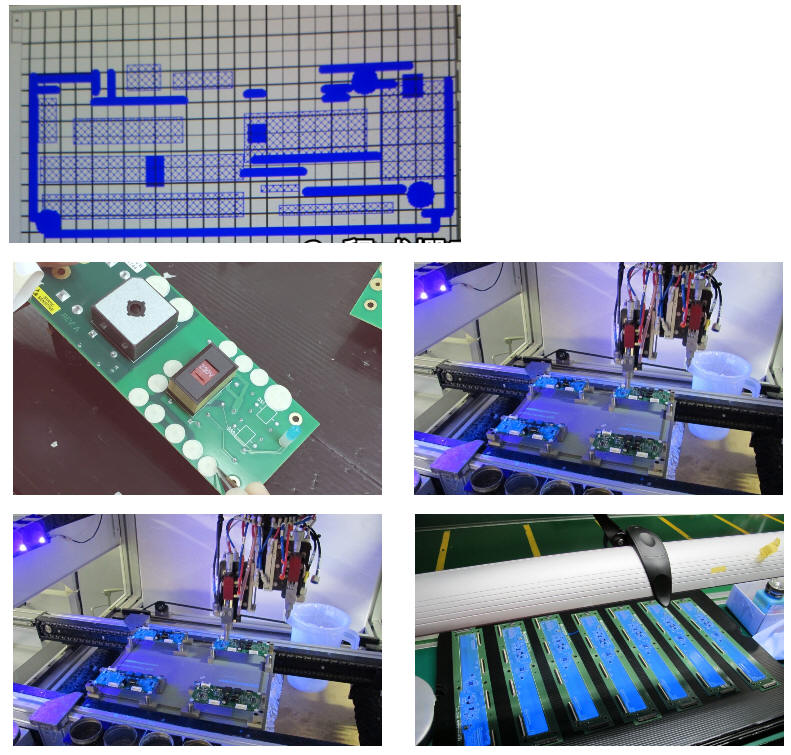

Conformal coatingonformal coating

- Professional Conformal Coating Automatic Application Line.

- Provide material selection (acrylic and silicon …) for conformal coating

- Production processes can be selected per products and the features of conformal coating by

Dipping, spraying; by hand or automatic machine.

The three flexible lines of SMT capacity configuration that best suits customers’ specified product

component number or precision.

All lines are equipped with an EKRA automatic printer to improve the process yield.

Three units of TRI AOI products all undergo AOI testing to improve the product yield.

Whole area is entirely protected by static electricity to ensure products are free from static electricity

damage.

With care of every single details and great customer service, we use precise SMT equipment and process management to achieve competitive cost and quick delivery to satisfy our customers.

Nitrogen Generator X-Ray Inspection

DIP/TEST/REPAIR

- Flexible deployment of the number of operators according to customers’ demand.

- Switchable disposable processes and washing processes

- Double-sided processes for PCB boards with thicknesses 2.5mm~3.5mm.

System burn-in room with a capacity of 200pcs.

ICT Test Station:

Equipment model :TRI Innovation TR-518FR

Electronic board processes OPEN/SHORT and defective parts testing.

BGA Repair:

Equipment model : Fine-Tech Electronics BGA 936USB

BGA Parts Repair and Replacement

Conformal coatingonformal coating

- Professional Conformal Coating Automatic Application Line.

- Provide material selection (acrylic and silicon …) for conformal coating

- Production processes can be selected per products and the features of conformal coating by

Dipping, spraying; by hand or automatic machine.

System Assembly System Assembly

System Assembly Line:

Flexible deployment of the number of operators according to customers’ demand.

Processes and Equipment: